Industrial automation plays a crucial role in modern industries by optimizing production, reducing downtime, and ensuring consistent quality.

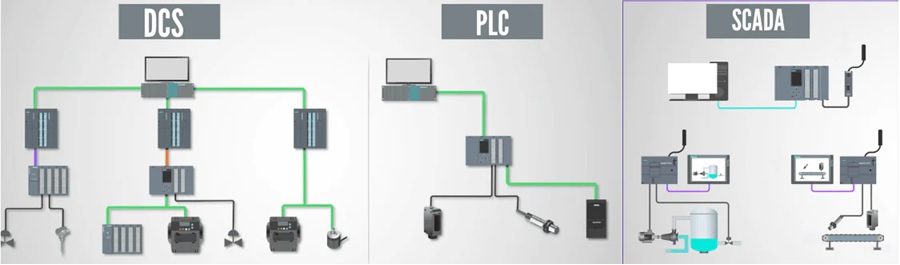

PLC, SCADA, and DCS each play different roles. PLC is a Programmable Logic Controller used to control specific operations; DCS is a Distributed Control System suitable for controlling an entire factory; while SCADA is software used for monitoring and data acquisition.

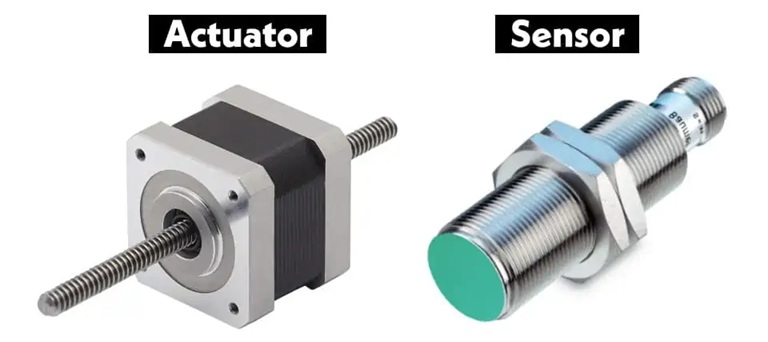

Sensor and actuators are basic elements in numerous electrical and mechanical structures. The sensors are made to identifying changes within an environment while actuators are made of performing certain actions in response to these detections. These should work within robotics, automation, as well as control systems.

Operate and monitor your system states efficiently with Human Machine Interfaces (HMIs) and industrial PCs (IPCs). Benefit from maximum scalability for the operating concept of your automation solution. Perform demanding control and networking tasks in a straightforward manner with intelligent industrial PCs. At the same time, the sophisticated visualization software supports fast and safe intervention in machine processes.

The proper descriptions of digital message formats as well as rules are known communication protocols. The main function of these protocols is to exchange messages from one computer system to another. These are significant in Automation systems as they consistently send and receive messages for control and monitoring. These protocols cover error detection & correction, signalling, and authentication. They can also explain the semantics, syntax & brings analog & digital communications together.

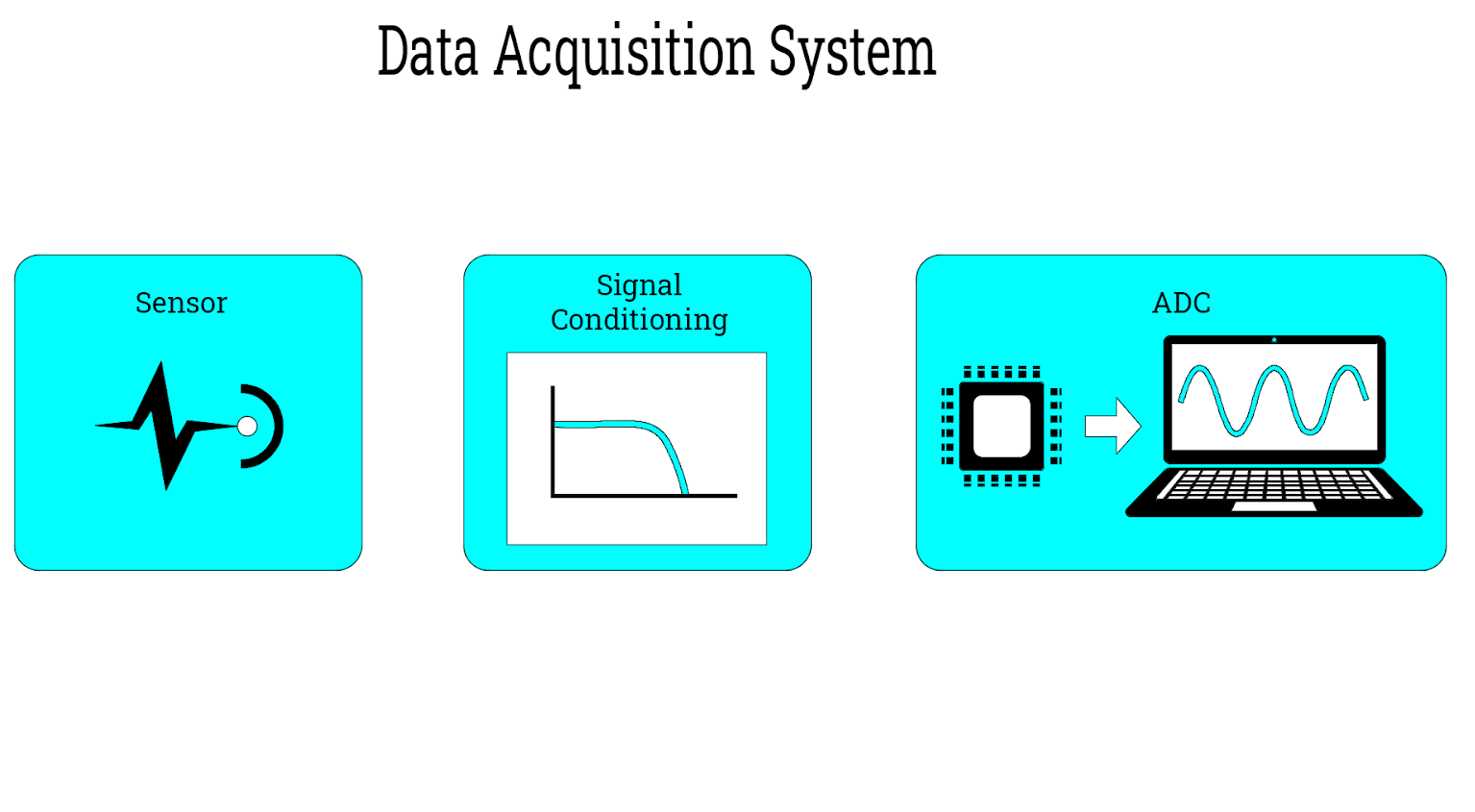

Data acquisition plays a crucial role in various industries and disciplines. It involves gathering, analyzing, and utilizing essential data to ensure accurate measurements, real-time monitoring, and informed decision-making. De¬spite offering advantages like precision and automation, data acquisition systems can be complex and costly.

Industry 4.0 refers to a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data. It includes cyber-physical systems, the Internet of things, cloud computing and cognitive computing. Industry 4.0 is commonly referred to as the fourth industrial revolution. Industry 4.0, also sometimes referred to as IIoT or smart manufacturing, marries physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better connected ecosystem for companies that focus on manufacturing and supply chain management. The need for connectedness and access to real-time insights across processes, partners, products, and people is the demand of the future.